There are a multitude of conveyor types, designs, and processes. The most common types are belt, roller, and overhead with overhead and floor mounted being the two broad categories. Conveying systems have as many benefits as there are types and are a normal part of large scale operations.

Types of Conveyor Systems

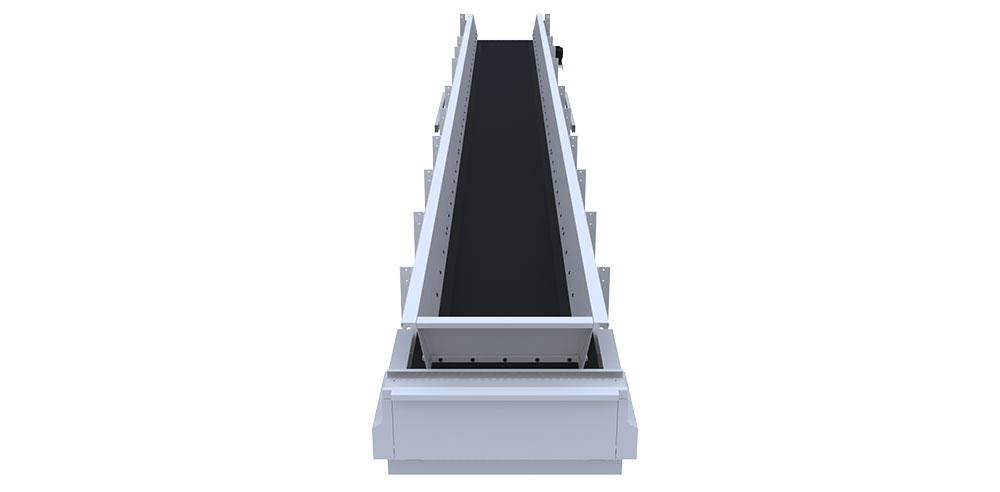

Belt Conveyors:

Belt conveyors are the most common and simplest form of conveyor and can have variable speeds. They have a moving belt that rests on a steel frame that supports the belt and the materials being moved. Ones that have a supporting frame underneath are referred to as sliding style. When the belt is supported by closely placed rollers, it is called a roller belt style.

Gravity Roller Conveyors:

Gravity roller conveyors have a set of equally spaced rollers connected to a side frame. The position of the rollers provides a surface to place materials for movement. If a gravity roller conveyor is tilted or mounted on an angle, materials move by gravity. Though pieces of varying sizes can be loaded on a gravity roller conveyor, workers need to be cautious of larger materials running into smaller ones. Gravity roller conveyors are used by shipping companies to load and unload trucks.

Chain Conveyors:

Chain conveyors can have two or several sets of chains that make contact with the bottom of items to be moved. The materials rest on the chains as they are moved. Chain driven conveyors are ideal for items with uneven bottom surfaces or ones that are very heavy. Ones that have a heavy frame can have pallets placed directly on them. Due to the types of items chain conveyors move, they operate very slowly.

Motorized Roller Conveyors:

Motorized roller conveyors use motors, placed along the conveyor frame, to power evenly spaced rollers. The design is similar to a gravity conveyor with the addition of motors. The number of motors is dependent on the load to be moved and the overall design of the system. The connection between the rollers can be a chain or belt. In some systems, there is a sensor that starts and stops the motor to avoid pieces getting packed together.

Slat Conveyors:

Slat conveyors have the same design as chain conveyors with flat slats connected to the chain. In some ways, they are similar to belt conveyors with slats replacing the belt.

The slats have a very smooth surface that prevents damage or harm to items being moved, making them ideal for assembly applications. Since the surface is smooth and without obstructions, slat conveyors can be loaded and unloaded using robotic automation.

Overhead Trolley Systems:

Overhead, trolley track systems can be manually or motor powered. They use an enclosed track or “I” beam and can move parts through finishing operations, drying booths, or supply assembly lines.

Monorail Conveyors:

Monorail conveying systems have carriers to move materials and are ideal for use over long distances. Rails are suspended from the structure of the building and have power supplied by signal lines from conductor lines inside the mounted rails. Monorail conveyors make use of the space above the production area. In some designs, the carriers lower to the level of production and then go up, out of the way.

Power and Free Conveyors:

Power and free conveying systems are designed to move parts through the production and assembly process. Items being assembled move from workstation to workstation. They stop at each station to be worked on and then move on. Power and free systems are a special form of overhead conveying system.

Inverted Conveyors:

Inverted conveyors are floor mounted and can be used as power and free conveyors. They normally have a drive system that does not involve a belt or chain.

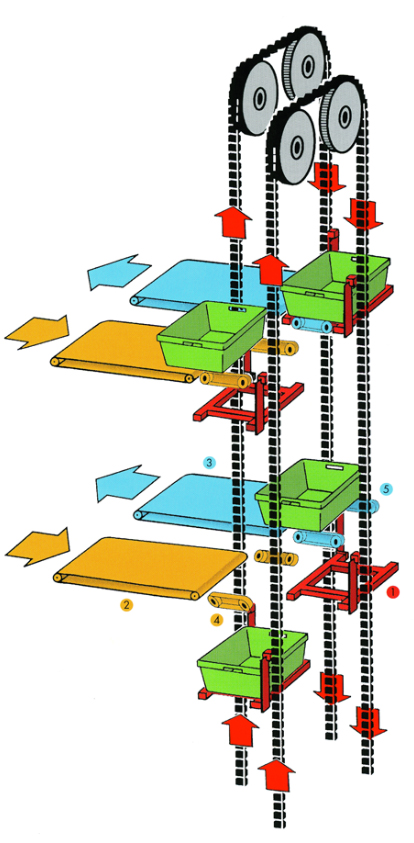

Paternoster Conveyors:

Paternoster conveyors are a vertical conveying system that uses equal spaced load carriers connected to a chain drive, which moves in a continuous loop. They are also known as platform conveyors.

Chute Conveyors:

Chute conveyors have a smooth flat surface made of wood, metal, or plastic that is set on an angle in a frame, which can be straight, spiral, or circular. Items are slid down the surface.

Screw Conveyors:

Screw conveyors are used to move bulk substances such as granular products, chips, and loose materials. The central part of a screw conveyor is a rotating helicoid on a shaft inside a pipe. Screw conveyors are known as auger, helix, and spiral conveyors. The blades of the screw flights are designed to carry the material upwards.

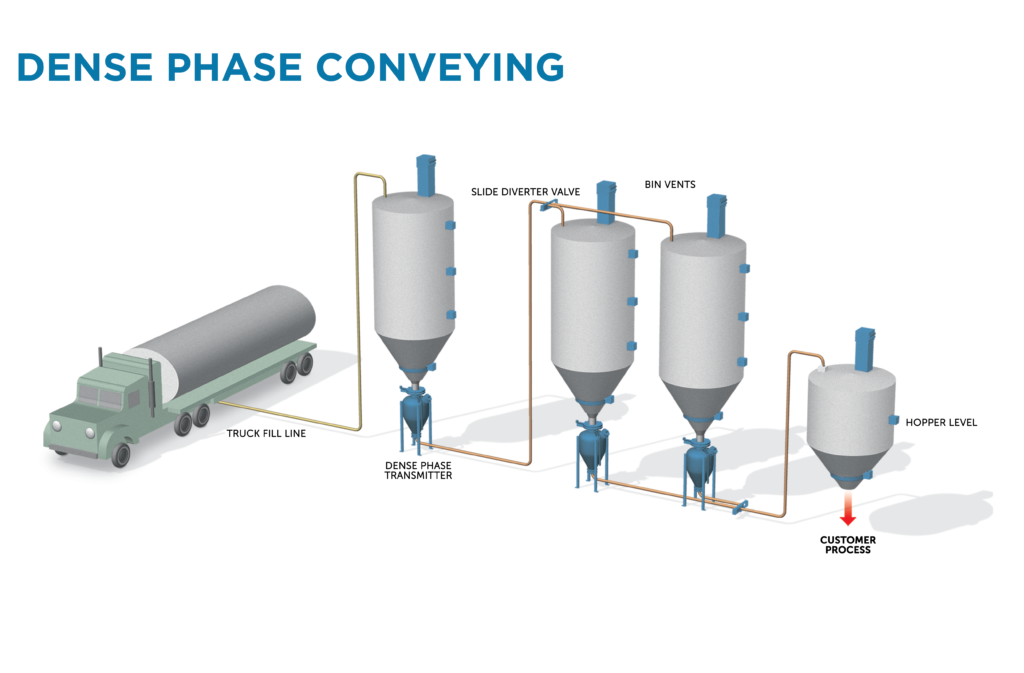

Pneumatic Conveyors:

Pneumatic conveyors transport bulk materials using a pressurized gas that pushes the material through a sealed pipeline. As the pressure builds in the pipeline, powders or granular materials are lifted and moved through the pipe.

Vibratory Conveyors:

A vibrating conveyor uses vibrations to move materials along a conveying trough and is ideal for materials such as grains, various solids, vegetables being picked in a field, and quarried rocks. The agitations and constant motion gently moves products through the use of vibration cycles. Each form of vibratory conveyor has a specific design to fit its function with ones for mining being radically different from those made for harvesting and food production.

A major benefit of vibrating conveyors is their excellent performance in the harshest conditions and environments.

The original article found here