- Main Menu

- About LVP

- Main Menu

- Our Products

- Main Menu

- LVP Industries

- Main Menu

- Conveyors

- Conveyors Types

- Main Menu

- Our Products

- Industrial Robots & Cobots

- Main Menu

- Our Products

- Labelling and Marking

- Main Menu

- Our Products

- Secondary Packaging

- Main Menu

- Our Products

- Primary Packaging

- Main Menu

- Our Products

- Warehouse Technology & Storage Systems

- Main Menu

- Our Products

- Motors

- Main Menu

- Our Products

- Layer Palletisers

- Main Menu

- Our Products

- Vision Systems

- Main Menu

- Our Products

- Strappers & Wrappers

- Conveyors

- Conveyors Types

- Roller Conveyors (Powered & Gravity)

- Conveyors

- Conveyors Types

- PU/PVC Belt Conveyors

- Conveyors

- Conveyors Types

- Plastic Belt Conveyors

- Conveyor Type

- Roller Conveyors (Powered & Gravity)

- Powered Roller Conveyors

- Conveyors

- Conveyors Types

- Pallet Conveyors

- Conveyor Type

- Roller Conveyors (Powered & Gravity)

- Gravity Roller Conveyors

- Conveyor Type

- Plastic Belt Conveyors

- Slat Chain Conveyors

- Main Menu

- LVP Services

- Main Menu

- Technical Documents

- Technical Documents

- Mini Belt Conveyor Range - Stainless

- Technical Documents

- Plastic Belt Conveyor Range

- Technical Documents

- Mini Belt Conveyor Range - Aluminium

- Main Menu

- Conveying Technology

- Main Menu

- Our Products

- Autonomous Mobile Robot (AMR)

Automotive Conveyor Systems

Press Brake Centralising for Automotive Industry

At LVP Automation, we provide advanced conveyor systems for the automotive industry. Our Press Brake Centralising Conveyor is designed to handle aluminium blanks for automotive radiators, feeding them into a 400-ton press while ensuring precision and efficiency. This system is equipped with Oriental stepper motors to centralise blanks, and includes an extendable conveyor to streamline the shipping process by feeding finished blanks into crates.

The conveyor was entirely designed, motor-sized, programmed, and installed by LVP, including electrical panel building. Our robust design accommodates oily environments and allows for seamless integration with robot pickers and existing press controls.

Press Brake Centralising – Automotive Conveyor Systems Solutions & Benefits

- Multi-Size Blanks: Ability to centre 5 different sizes of aluminium blanks for increased flexibility.

- Durable Design: Constructed with steel and aluminium frames to withstand tough industrial conditions.

- Integrated Control Systems: Remote control panel for size selection, stop/start, and emergency stops, enhancing safety.

- Robot Integration: Seamless communication with robot pickers and press controls, improving automation efficiency.

- Stepper Motors: Stepper motor control for precise operation and easier setup compared to servo motors.

- Extendable Conveyor: Designed to feed finished blanks into shipping crates, improving workflow efficiency.

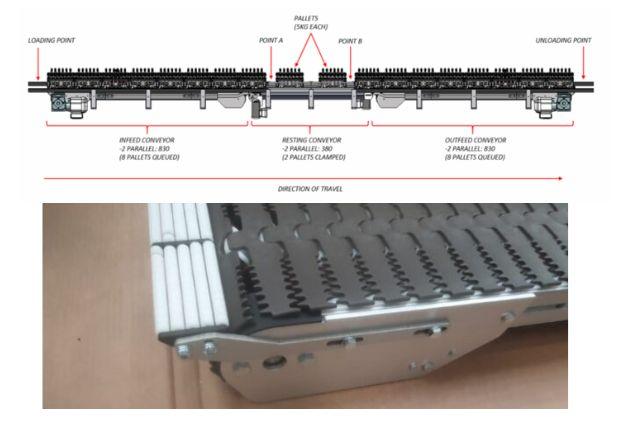

Low-Friction Transport – Automotive Conveyor Systems Solutions & Benefits

Under Pressure Conveyor Solutions for Automotive Applications

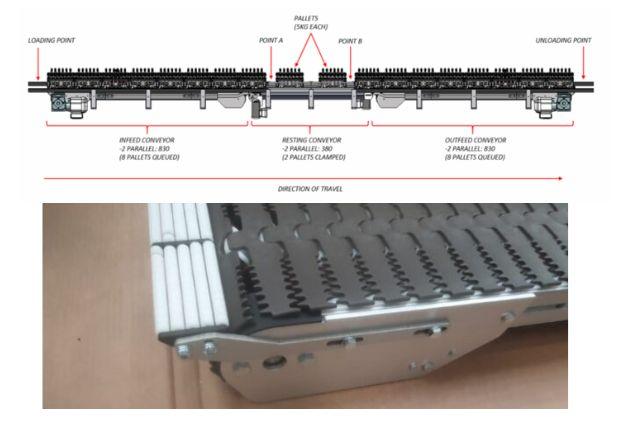

For automotive conveyor systems requiring minimal line pressure, LVP Automation has developed a solution to manage friction, heat, and noise, improving motor efficiency and reducing overcurrent events. Our Carryline 220mm Low Friction Conveyor was chosen for this application, featuring FG100P resin material that provides low friction and high durability.

This belt is also water-resistant and suitable for cleanroom environments, making it ideal for applications requiring cleanliness and toughness. The system also maintains a low heat gradient, ensuring a quieter and more efficient operation in automotive manufacturing.

Low-Friction Transport – Automotive Conveyor Systems Solutions & Benefits

- Low Friction Belt: Specially designed belt with FG100P resin for minimal friction, enhancing motor performance.

- Heat-Resistant Design: Built to maintain low heat gradients, reducing the risk of overheating during long operations.

- Low Noise Chatter: Quiet operation for environments sensitive to noise, improving working conditions.

- Durable and Tough: Water-resistant belt, ideal for cleanroom environments, and built to last in industrial settings.

Low-Friction Transport – Automotive Conveyor Systems Solutions & Benefits

Low-Friction Transport – Automotive Conveyor Systems Solutions & Benefits

Low-Friction Transport – Automotive Conveyor Systems Solutions & Benefits

Let's Connect

Have a question about our conveyor systems or need a tailored automation solution for your business? Our team at LVP Conveyors is here to help. Fill out the form below with your details, and we’ll get back to you as soon as possible. Whether you need a quote, technical support, or more information on our products, we’re ready to assist.

Need more help?

Sales

sales@conveyors.ie

Free Consultation

+ 353 1 8643838