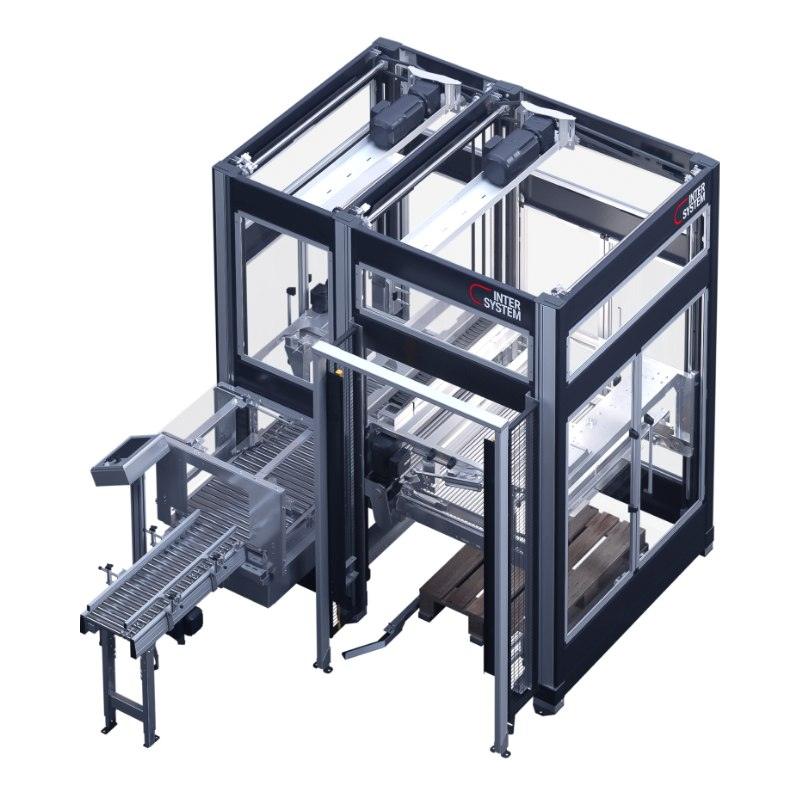

Semi-Automatic Palletizer – SEMI Series

Compact semi-automatic palletizer for low-capacity lines. The SEMI model stacks cases/bags/crates automatically while operators swap pallets manually. With low-level infeed, a safety light barrier and upgrade paths to automated pallet handling, it’s a reliable first step into palletizing—engineered and supported in Ireland.

Key Features & Benefits of the SEMI Palletizer

- Automatic stacking, manual pallet change — ideal for lower volumes

- Low-level product infeed for easy integration with existing lines

- Safety light barrier pauses the cell during pallet exchange

- Future-ready design — upgrade to auto pallet handling later

- Gentle product handling and accurate, stable stacking

- Compact footprint for tight end-of-line spaces

- Quiet, dependable operation with low maintenance