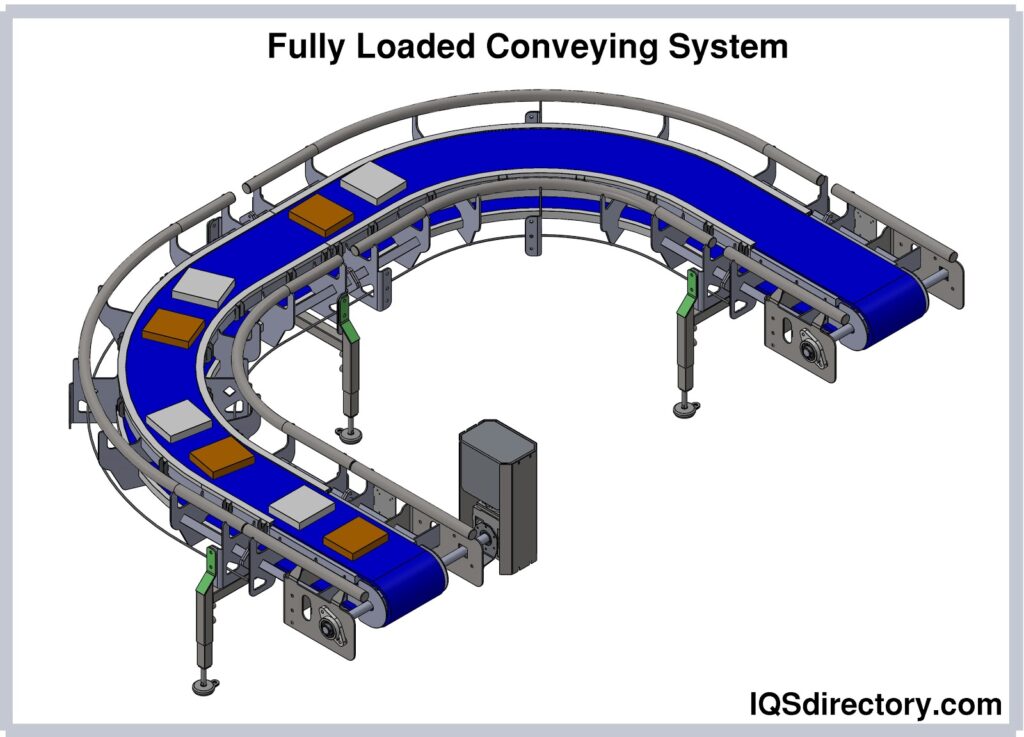

Conveyors have become an important part of manufacturing, mining, production, and finishing operations. They increase efficiency and help reduce labor costs. The use of conveyors has led to greater volume, increased production, and prevention of injuries.

Regardless of the industry, conveyors have been proven to be a boost for production processes.

Benefits of Conveying Systems

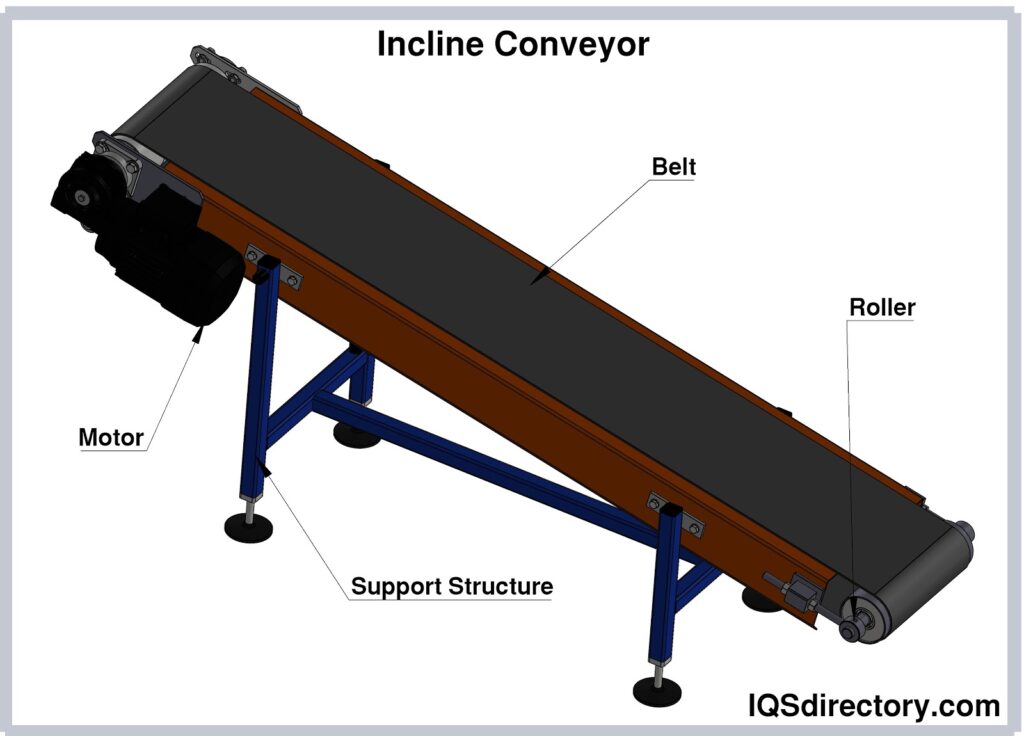

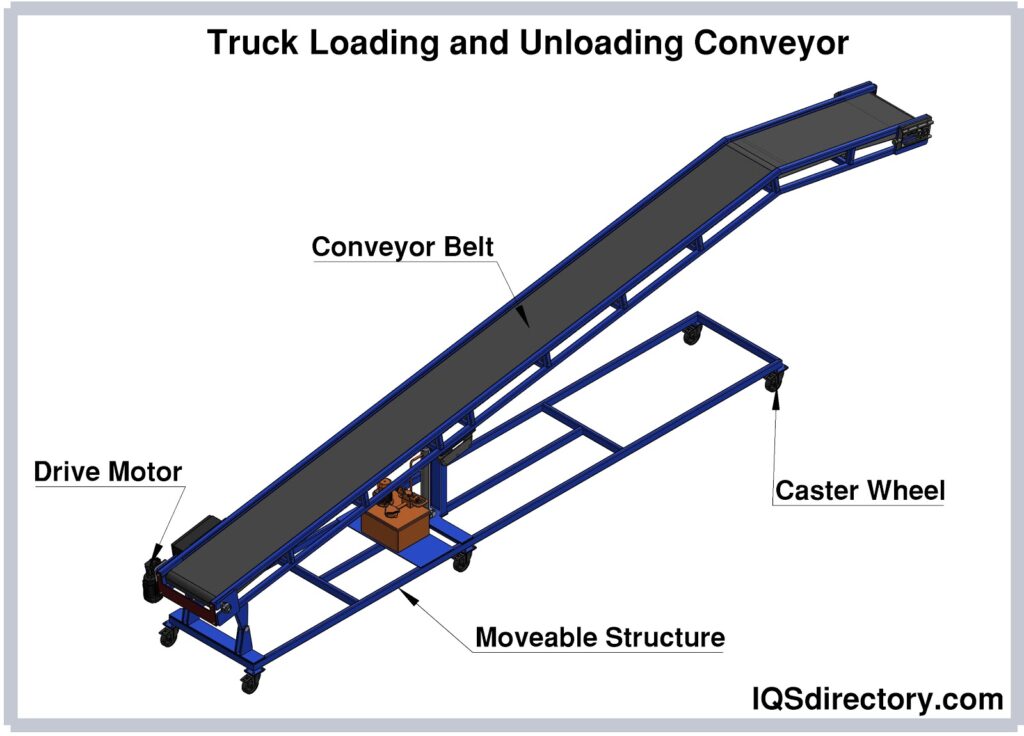

Time Savings:

Materials can be moved from location to location or from one level to another rapidly and easily.

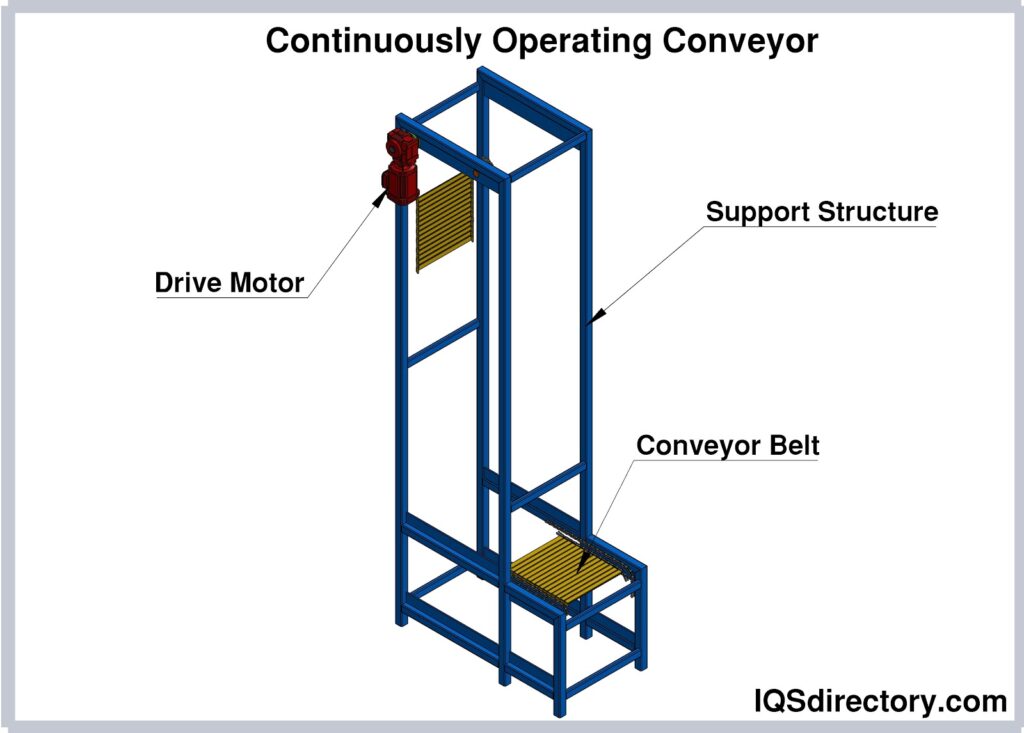

Continuous Operation:

Materials are continuously loaded and unloaded for long periods of time without interruption or stoppage.

Automated Unloading:

Conveyors can be designed to automatically unload materials without the need for manual labor.

Control of Movement:

Conveying systems have speed controls to monitor how rapidly items move along the system, which eliminates the concern for handling issues or breakage.

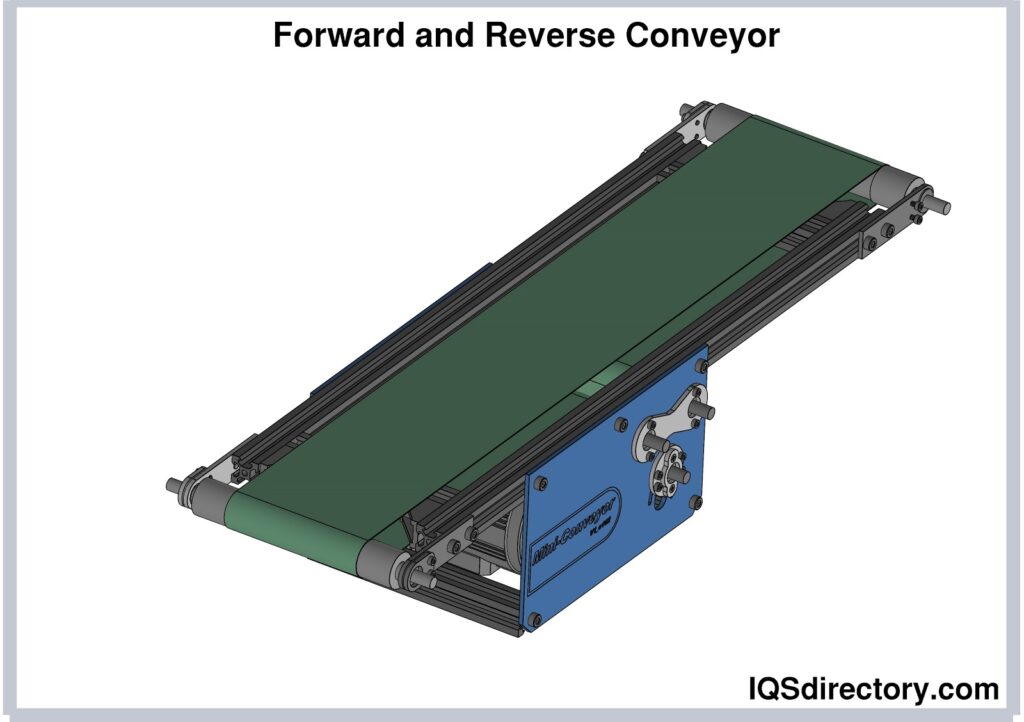

Directional:

Though older conveying systems were able to move in only one direction, modern conveyors, with CNC controls, can move in forward or back. This helps in adjusting manufacturing operations.

Low Maintenance:

The majority of conveyors require little maintenance, though there are some varieties with motors and parts that need to be continually checked and replaced. The need for maintenance depends on the conveyor’s use and environment.

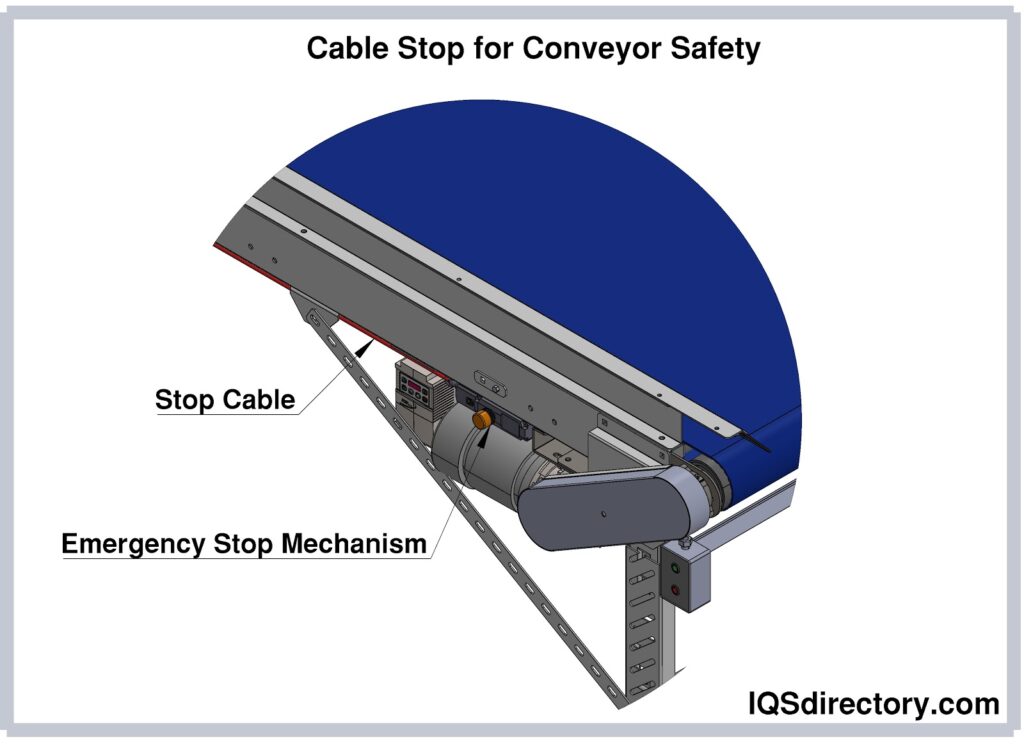

Safety:

Conveyors are the safest method for moving materials through a facility or production floor. They have built in on and off switches, emergency stop switches, and speed adjustments. The image below is of a safety cable stop for conveyors.

High Volume:

Conveyors are a part of an automated system capable of moving hundreds or thousands of tons of material per hour or in a day.