- Main Menu

- About LVP

- Main Menu

- Our Products

- Main Menu

- LVP Industries

- Main Menu

- Conveyors

- Conveyors Types

- Main Menu

- Our Products

- Industrial Robots & Cobots

- Main Menu

- Our Products

- Labelling and Marking

- Main Menu

- Our Products

- Secondary Packaging

- Main Menu

- Our Products

- Primary Packaging

- Main Menu

- Our Products

- Warehouse Technology & Storage Systems

- Main Menu

- Our Products

- Motors

- Main Menu

- Our Products

- Layer Palletisers

- Main Menu

- Our Products

- Vision Systems

- Main Menu

- Our Products

- Strappers & Wrappers

- Conveyors

- Conveyors Types

- Roller Conveyors (Powered & Gravity)

- Conveyors

- Conveyors Types

- PU/PVC Belt Conveyors

- Conveyors

- Conveyors Types

- Plastic Belt Conveyors

- Conveyor Type

- Roller Conveyors (Powered & Gravity)

- Powered Roller Conveyors

- Conveyors

- Conveyors Types

- Pallet Conveyors

- Conveyor Type

- Roller Conveyors (Powered & Gravity)

- Gravity Roller Conveyors

- Conveyor Type

- Plastic Belt Conveyors

- Slat Chain Conveyors

- Main Menu

- LVP Services

- Main Menu

- Technical Documents

- Technical Documents

- Mini Belt Conveyor Range - Stainless

- Technical Documents

- Plastic Belt Conveyor Range

- Technical Documents

- Mini Belt Conveyor Range - Aluminium

- Main Menu

- Conveying Technology

- Main Menu

- Our Products

- Autonomous Mobile Robot (AMR)

FMCG Conveyors

Baby Wipes Conveyor Solution

LVP Automation provided a conveyor solution for Irish Breeze, Ireland’s only manufacturer of soaps and cotton wool products. The challenge was to convey their patented wet wipes pack from a cleanroom to a packing area.

Baby Wipes Conveyor – FMCG Conveyors Solutions & Benefits

- Compact Conveyor Design: The Belcon mini series provides a space-efficient solution for moving products between processes.

- Cleanroom Compliance: The conveyor system ensures that the wet wipes are conveyed out of the cleanroom without contamination.

- 90-Degree Transfer Integration: A pusher mechanism was installed to handle the 90-degree product transfer seamlessly.

- Minimal Disruption: The system was fully integrated with existing conveyors, ensuring no disruption to the production line during installation.

- Cost-Effective Automation: LVP provided a budget-friendly solution with the Belcon mini series that maintained high productivity.

- Durable System: The Belcon mini series is known for its durability, reducing the need for frequent maintenance.

Brillo Pads Conveyor – FMCG Conveyors Solutions & Benefits

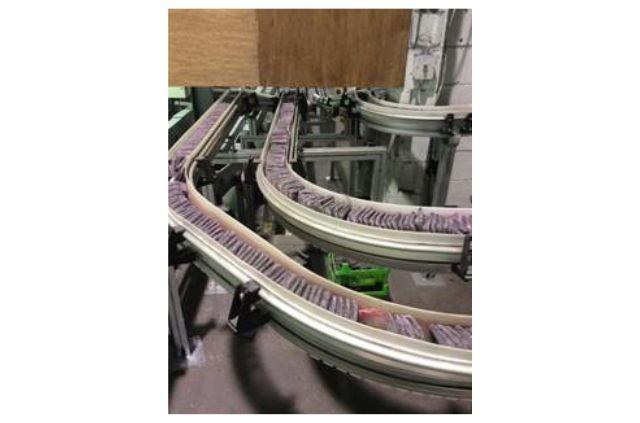

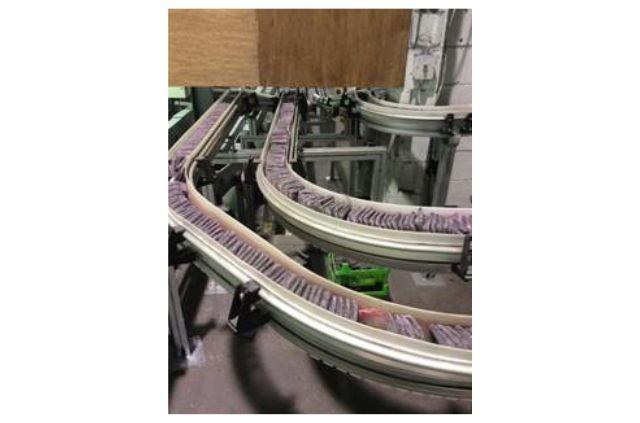

Brillo Pads Conveyor Solution

For Brillo Pads, an abrasive product, LVP Automation designed a wear-resistant automation line to handle the manufacturing and assembly process while minimising floor space usage.

Brillo Pads Conveyor – FMCG Conveyors Solutions & Benefits

- Wear-Resistant Conveyor System: The Acetal chain provides durability and abrasion resistance, making it ideal for handling the rough surface of Brillo Pads.

- Temperature-Resistant Materials: The conveyor line was designed to withstand high temperatures to allow the Brillo Pads to cure before assembly.

- Slow Speed Optimisation: SEW geared motors ensured slow, controlled movement, ideal for sensitive products like Brillo Pads.

- Space Efficiency: The 62mm chain design maximises space efficiency without sacrificing functionality.

Brillo Pads Conveyor – FMCG Conveyors Solutions & Benefits

Brillo Pads Conveyor – FMCG Conveyors Solutions & Benefits

Brillo Pads Conveyor – FMCG Conveyors Solutions & Benefits

Let's Connect

Have a question about our conveyor systems or need a tailored automation solution for your business? Our team at LVP Conveyors is here to help. Fill out the form below with your details, and we’ll get back to you as soon as possible. Whether you need a quote, technical support, or more information on our products, we’re ready to assist.

Need more help?

Sales

sales@conveyors.ie

Free Consultation

+ 353 1 8643838