- Main Menu

- About LVP

- Main Menu

- Our Products

- Main Menu

- LVP Industries

- Main Menu

- Conveyors

- Conveyors Types

- Main Menu

- Our Products

- Industrial Robots & Cobots

- Main Menu

- Our Products

- Labelling and Marking

- Main Menu

- Our Products

- Secondary Packaging

- Main Menu

- Our Products

- Primary Packaging

- Main Menu

- Our Products

- Warehouse Technology & Storage Systems

- Main Menu

- Our Products

- Motors

- Main Menu

- Our Products

- Layer Palletisers

- Main Menu

- Our Products

- Vision Systems

- Main Menu

- Our Products

- Strappers & Wrappers

- Conveyors

- Conveyors Types

- Roller Conveyors (Powered & Gravity)

- Conveyors

- Conveyors Types

- PU/PVC Belt Conveyors

- Conveyors

- Conveyors Types

- Plastic Belt Conveyors

- Conveyor Type

- Roller Conveyors (Powered & Gravity)

- Powered Roller Conveyors

- Conveyors

- Conveyors Types

- Pallet Conveyors

- Conveyor Type

- Roller Conveyors (Powered & Gravity)

- Gravity Roller Conveyors

- Conveyor Type

- Plastic Belt Conveyors

- Slat Chain Conveyors

- Main Menu

- LVP Services

- Main Menu

- Technical Documents

- Technical Documents

- Mini Belt Conveyor Range - Stainless

- Technical Documents

- Plastic Belt Conveyor Range

- Technical Documents

- Mini Belt Conveyor Range - Aluminium

- Main Menu

- Conveying Technology

- Main Menu

- Our Products

- Autonomous Mobile Robot (AMR)

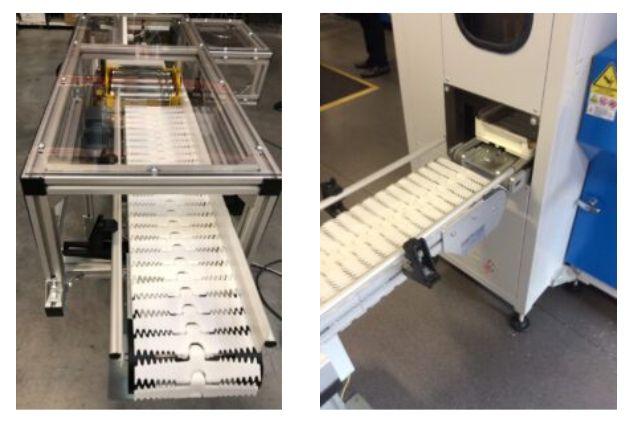

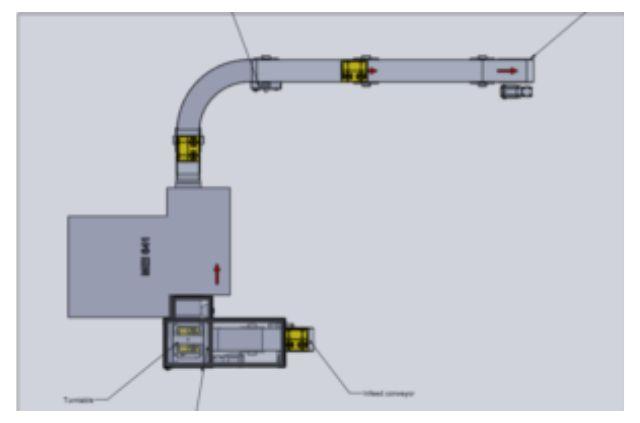

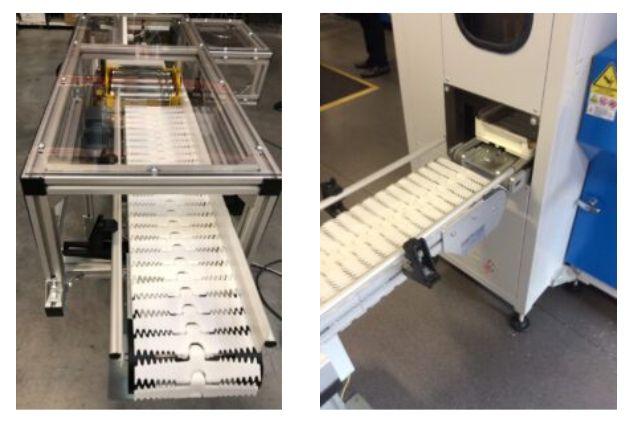

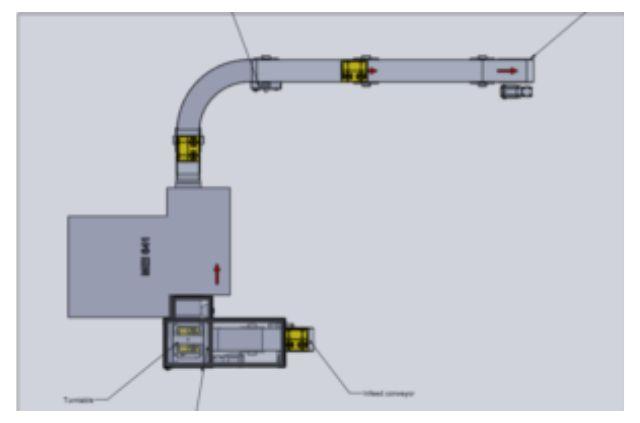

Optical Lens Handling Conveyors

Lens Tray Conveying to Bisphera Machines

LVP Automation installed a sophisticated lens tray handling conveyor line at a leading optical lens manufacturer in Manchester. This project, located in Altrincham, built upon the success of a previous installation from 2010 and was designed to enhance the efficiency and precision of the lens manufacturing process.

Lens Tray Conveying – Optical Lens Handling Solutions & Benefits

- Automated Lens Tray Delivery: The system provides fully automated delivery of plastic trays carrying delicate lenses, ensuring they are transported to and from Bisphera machines with minimal handling.

- Precise Orientation: The use of pneumatic rotating turntables allows for accurate orientation of lens trays, which is crucial for the finishing machines to perform cutting and bevel etching effectively.

- Seamless Integration: The conveyor system features interlocking with the lens machines, enabling synchronised operations and improving overall workflow efficiency.

- User-Friendly Controls: Equipped with a mild steel control panel featuring AB PLC and inverter control, the system allows for easy operation and site commissioning.

- Modular Design: The system's low-maintenance and modular design ensure that it remains aesthetically pleasing while meeting rigorous operational standards.

- Maintenance Accessibility: The design allows for easy access to maintenance areas, promoting quick servicing and reducing potential downtime.

Optical Lens Handling Conveyor – Solutions & Benefits

Optical Lens Handling Conveyor Solution

LVP Automation completed the installation of an advanced lens tray handling conveyor line for one of Manchester’s leading optical lens manufacturers. This project, located in Altrincham, is based on the successful integration of a similar system installed in 2010, aiming to optimise the lens manufacturing process.

Optical Lens Handling Conveyor – Solutions & Benefits

- Comprehensive Handling System: The conveyor line manages the delivery of lens trays into and out of Bisphera machines, enhancing the overall efficiency of the lens production process.

- Durable Construction: All conveyors are built with aluminium Carryline 140mm wide plastic chain, ensuring strength and reliability in handling delicate products.

- Efficient Product Flow: The system facilitates smooth transportation of lens trays, minimising the risk of damage during movement.

- Control and Safety Features: The conveyor system includes CE machine guarding and a PLC control system, ensuring operational safety and compliance.

Optical Lens Handling Conveyor – Solutions & Benefits

Optical Lens Handling Conveyor – Solutions & Benefits

Optical Lens Handling Conveyor – Solutions & Benefits

Let's Connect

Have a question about our conveyor systems or need a tailored automation solution for your business? Our team at LVP Conveyors is here to help. Fill out the form below with your details, and we’ll get back to you as soon as possible. Whether you need a quote, technical support, or more information on our products, we’re ready to assist.

Need more help?

Sales

sales@conveyors.ie

Free Consultation

+ 353 1 8643838