Barcode Verification

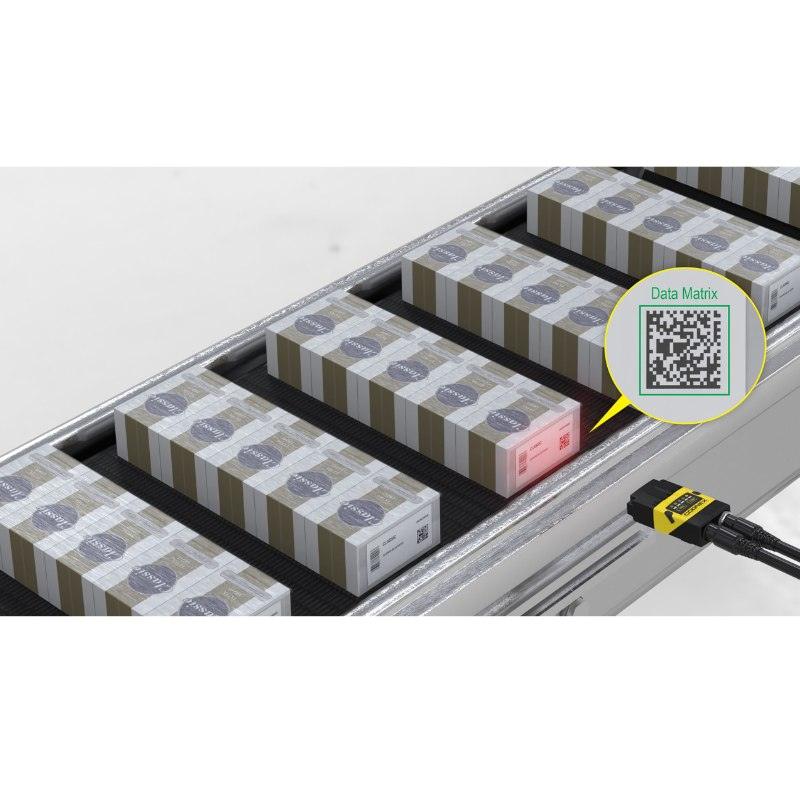

Our advanced barcode scanning solutions provide high-speed, reliable scanning to optimise product traceability, inventory management, and workflow efficiency. Partnering with industry leaders Cognex, Keyence, and SICK, we offer barcode scanners that deliver precision, durability, and adaptability across diverse applications. Engineered to meet the needs of various industries, these solutions enhance inventory tracking, product verification, and operational efficiency with exceptional accuracy and speed.

Key Features & Benefits Barcode Verification

- High-speed, reliable scanning for 1D/2D (GS1-128, EAN, DataMatrix, QR, UDI)

- Exceptional Precision and Durability: Robust scanners built to withstand demanding environments while maintaining performance.

- Versatile Application: Ideal for inventory tracking, product verification, and improving overall operational workflow.

- Partnership with Cognex, Keyence, and SICK: Utilises cutting-edge technology from leading providers for unparalleled performance.

- Adaptable to Industry Needs: Customisable scanning solutions tailored to meet specific industry and workflow demands.