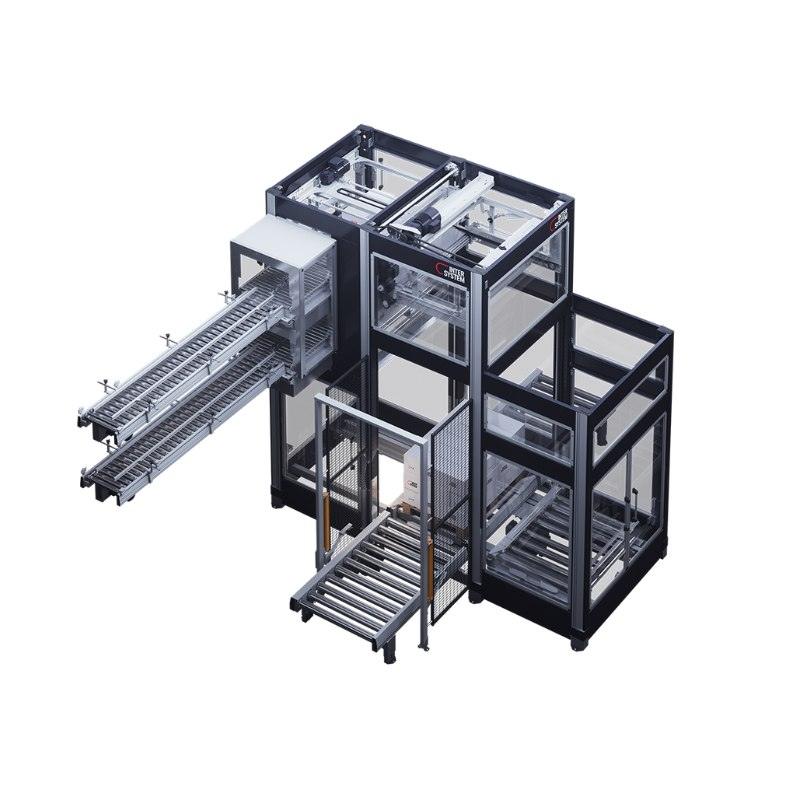

Multi-Line Palletiser – MULTI Series

The MULTI Palletiser is engineered to handle two or three production lines simultaneously, providing a versatile, cost-effective solution for medium-capacity palletising. With an integrated pallet exchange system, the MULTI Palletiser ensures that the correct pallet is always precisely positioned for loading, enhancing efficiency and reducing downtime. Its space-saving, two-level design maximises floor space, making it ideal for facilities looking to optimise both productivity and layout.

Key Features & Benefits of the MULTI Palletiser

- Two–three line management for medium-capacity operations

- Integrated pallet exchange keeps loading continuous and accurate

- Space-efficient two-level design to maximise floor area

- Cost-effective alternative to multiple single-line machines

- Precise, stable stacking with gentle product handling

- Recipe-based patterns for fast SKU/pallet size changeovers

- Flexible layouts (left/right hand) to fit existing ends-of-line