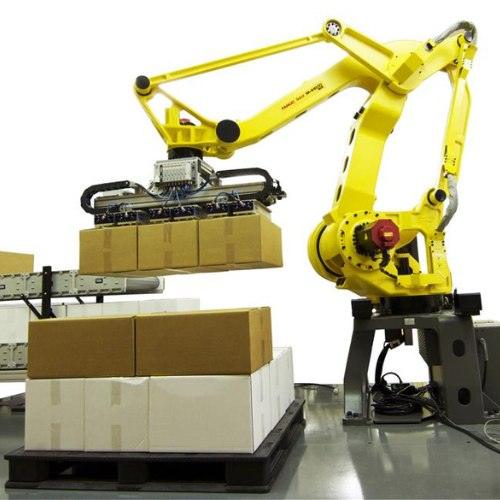

Palletizer

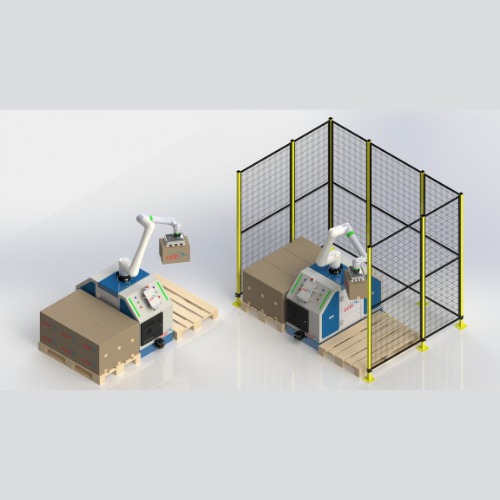

Fanuc’s industrial robot palletizer are built to enhance throughput and boost efficiency in demanding production environments. Designed for continuous operation, these robust robots offer faster cycle times and are capable of handling heavy payloads, making them ideal for complex mixed or standard palletising tasks. Equipped with adaptable software, Fanuc palletisers automatically adjust to new requirements without the need for reprogramming, providing a versatile solution that streamlines operations and reduces downtime.

Key Features & Benefits of the Palletizer

- High-Speed, Continuous Operation: Engineered for uninterrupted performance and faster cycle times, optimising productivity.

- Heavy Payload Capacity: Handles a wide range of products, including heavy or bulk items, ensuring flexibility across applications.

- Adaptable Software: Eliminates the need for reprogramming, allowing the system to adjust to different palletising tasks efficiently.

- Versatile Task Handling: Suitable for both mixed and standard palletising tasks, accommodating a variety of product types and packaging configurations.