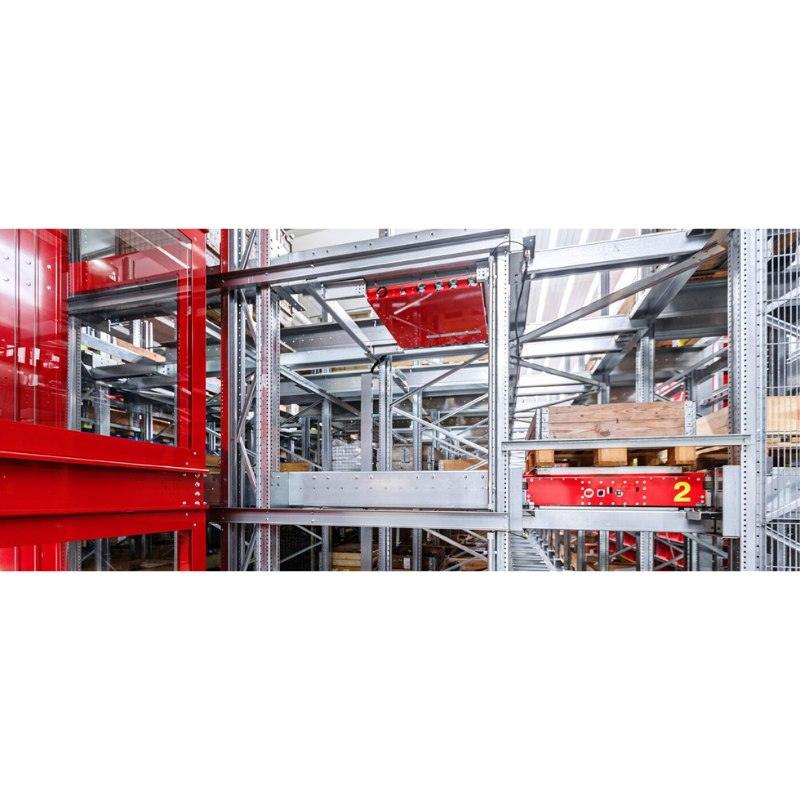

Shuttle Systems

Gebhardt’s shuttle systems, including the StoreBiter® MLS, OLS, and OLS X models, are designed to provide dynamic and efficient storage and retrieval solutions for a variety of goods, including containers, trays, and cardboard boxes. These flexible systems support various storage depths and configurations, ensuring high performance and energy efficiency in diverse warehouse environments. Select models feature double-layer capacitors for energy savings, enhancing operational efficiency. Gebhardt’s shuttle systems can be seamlessly integrated with Goods-to-Person workstations, optimising workflows and improving productivity.

Key Features & Benefits of the Shuttle System

- Flexible Storage Depths and Configurations: Adapts to a wide range of storage layouts and depths, providing versatility across warehouse applications.

- High Performance with Energy Efficiency: Advanced models include double-layer capacitors for enhanced energy savings.

- Multiple Model Options: Choose from the StoreBiter® MLS, OLS, and OLS X models to meet specific storage needs.

- Integration with Goods-to-Person Workstations: Supports streamlined operations by optimising retrieval and picking efficiency.

- Adaptable for Various Warehouse Sizes: Suitable for both small and large-scale warehouse environments.