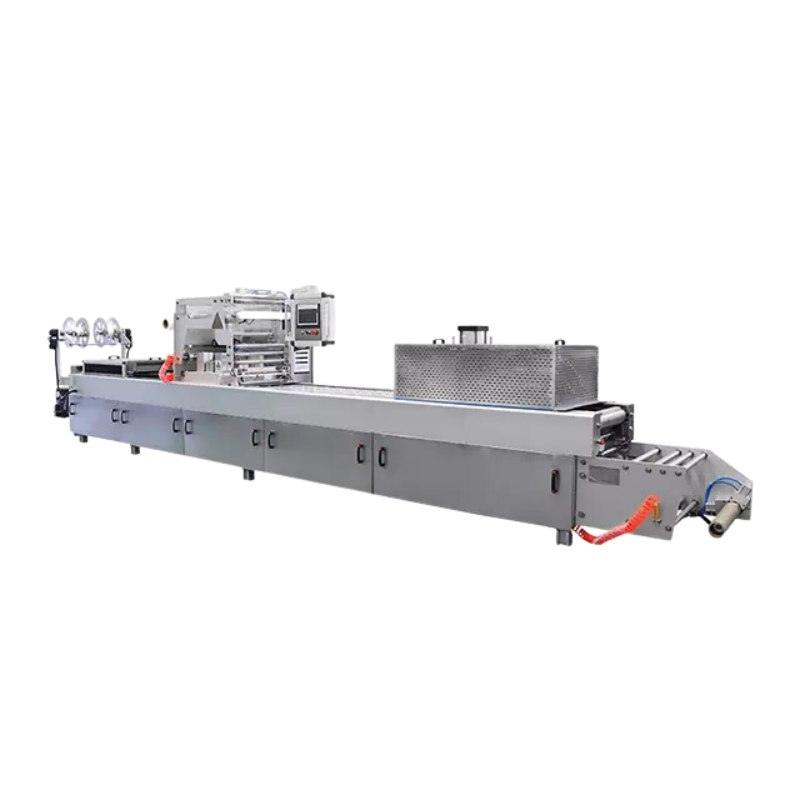

Thermoforming Machines

LVP Automation provides advanced thermoforming machines engineered to create durable and customised packaging for a variety of products. Using heat and vacuum technology, our thermoformers precisely mould plastic sheets into tailored shapes, delivering secure packaging solutions for industries such as food, medical, and electronics. Designed for high-speed production, these machines offer reliability, adaptability, and efficiency, helping businesses meet unique packaging requirements with ease.

Key Features & Benefits of Thermoforming Machines

- Customisable Designs: Enables creation of packaging that fits product specifications exactly, enhancing both protection and presentation.

- Efficient Production: High-speed forming capabilities shorten production time, making these thermoformers ideal for high-volume operations.

- Material Versatility: Compatible with various plastic materials, including recyclable options, supporting sustainability efforts.

- Easy Integration: Seamlessly integrates into existing production lines, improving workflow and productivity without major adjustments.