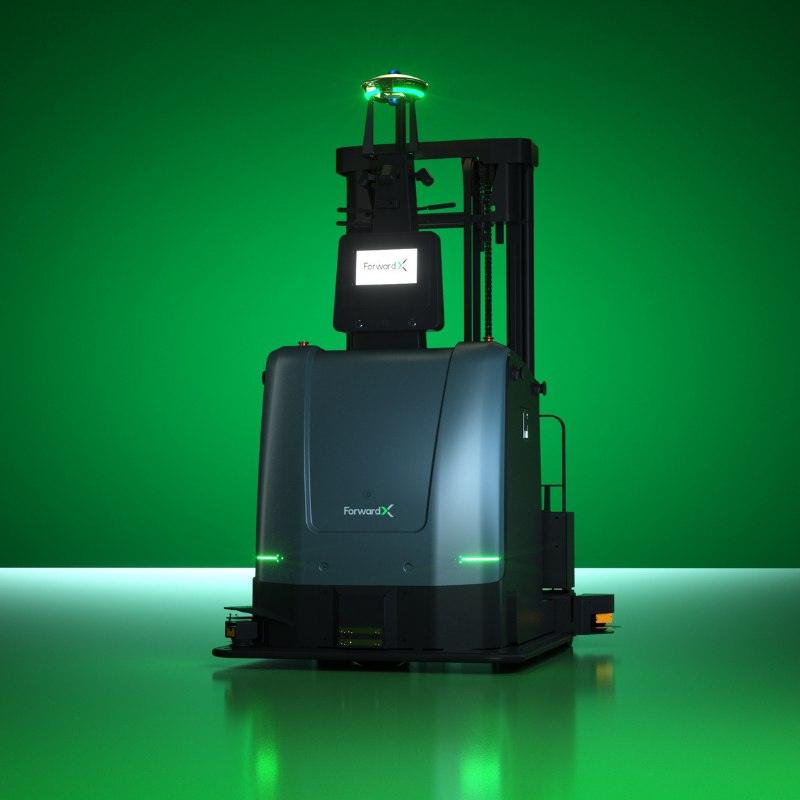

Autonomous Forklifts – Apex Series

High-performance autonomous forklifts that lift, stack and transport pallets safely and efficiently. The Apex Series spans the Apex1400-L Pallet Stacker, Apex C1500-L Counterbalanced, Apex 2000 Pallet Jack and Apex 1500 Pallet Jack—engineered to boost throughput, cut handling costs and improve safety in live warehouse environments.

Key Features & Benefits of the Apex Autonomous Forklifts

- Model range for every task: stacker, counterbalanced and pallet jack variants

- Safe navigation in live aisles: LiDAR/vision, obstacle detection, certified safety

- Seamless WMS/WES integration: missions from orders; live status & confirmations

- High uptime: smart charging/auto-dock and health monitoring reduce downtime

- Scalable fleets: start small and add vehicles/missions as volumes grow

- Consistent handling: precise fork positioning, height control and pallet detection

- Fast deployment: minimal infrastructure with SLAM mapping and quick commissioning