Chain Conveyor

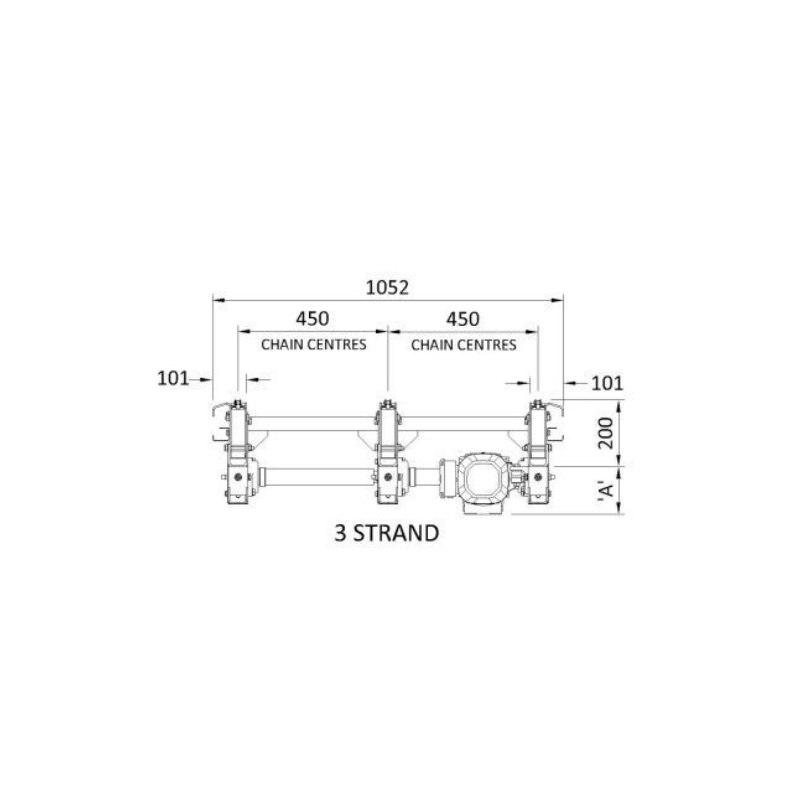

Our painted steel chain straight conveyors are engineered specifically for high-capacity pallet handling in demanding industrial environments. Designed for durability, these conveyors feature triple strand chains running on wear-resistant polymer guide strips, ensuring stable and smooth pallet transport. With adjustable height, multiple length options, and a protective painted finish, this conveyor system offers a reliable, low-maintenance solution for heavy-duty applications.

Key Features & Benefits of the Chain Conveyor

- Load Capacity: Supports up to 1500kg per pallet, providing strength for high-demand transport tasks.

- Chain Guide: Triple strand chains run on durable polymer guide strips, reducing wear and enhancing operational smoothness.

- Height Range: Adjustable from 425mm to 1175mm, accommodating various installation needs.

- Standard Lengths: Available in lengths from 1300mm to 3600mm to suit different configurations.

- Motor Options: Power options range from 0.75 kW to 3.0 kW for flexible performance.

- Speed Options: Conveyor speeds available at 12, 15, or 18 metres per minute to match operational requirements.

- Easy Chain Tensioning: Simple tension adjustment for minimal maintenance and maximised uptime.