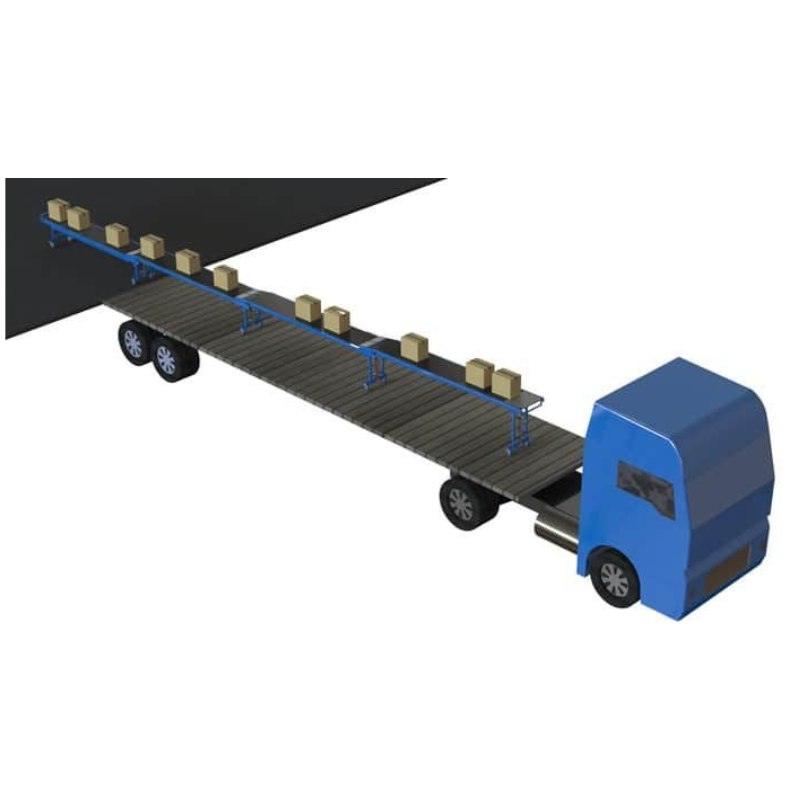

Vehicle Loading Conveyors

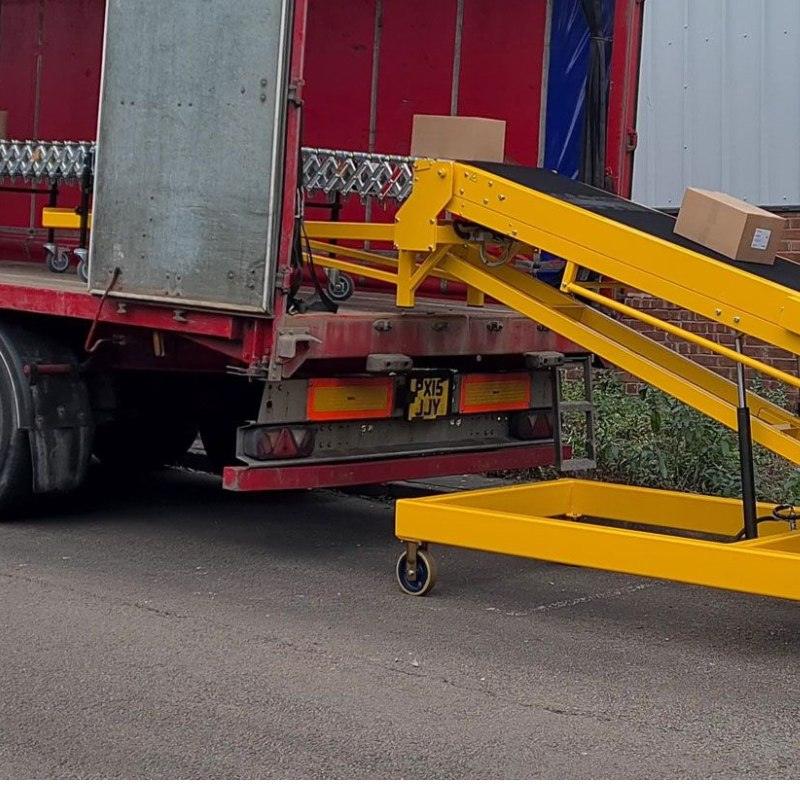

LVP Automation offers a versatile selection of powered and gravity conveyors specifically designed for efficient vehicle and container loading and unloading. Engineered for durability and ease of operation, these conveyors streamline workflows and improve handling efficiency for 20ft and 40ft containers or trailers. With a focus on reliable performance, they provide a practical, long-lasting solution for high-demand loading tasks.

Key Features & Benefits of the Vehicle Loading Conveyor

- Powered and Gravity Conveyor Options: Choose from powered units for added control or gravity options for simplicity and cost-effectiveness.

- Durable Construction: Built to withstand rigorous use, ensuring smooth operation in high-traffic loading areas.

- Optimised for Containers and Trailers: Ideal for 20ft and 40ft container and trailer loading, enhancing operational efficiency.

- Efficient Loading and Unloading: Streamlines workflows, reducing manual effort and expediting loading and unloading times.