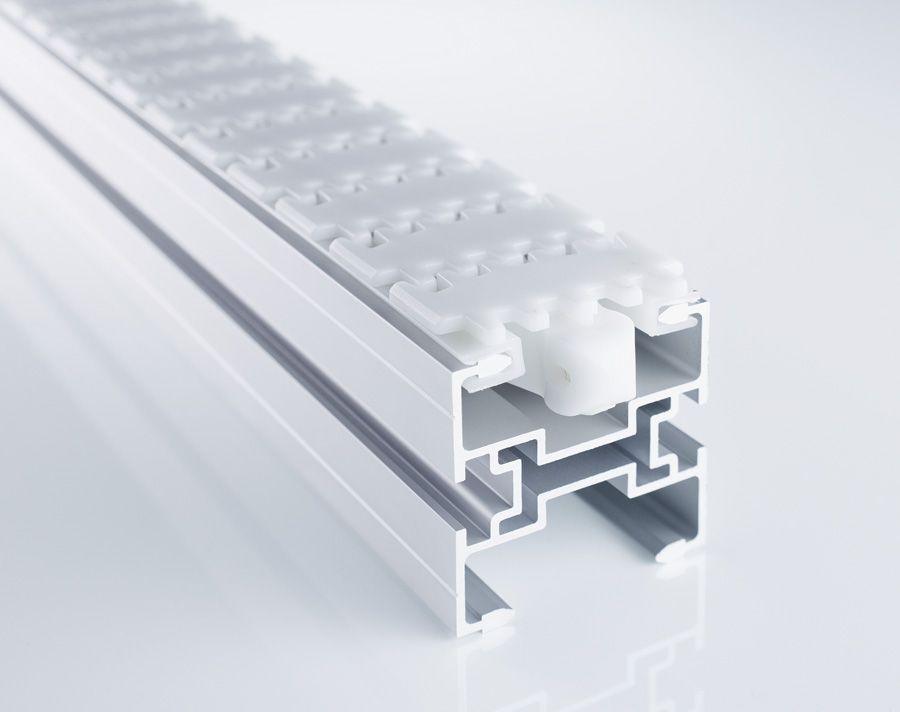

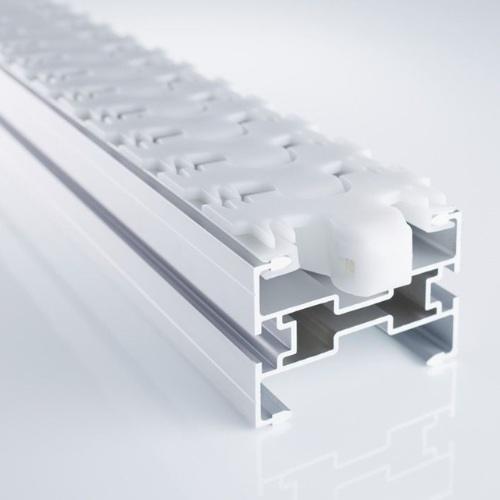

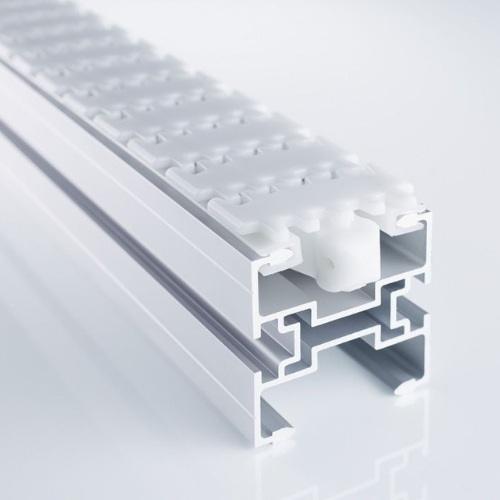

Aluminium Slat Conveyors

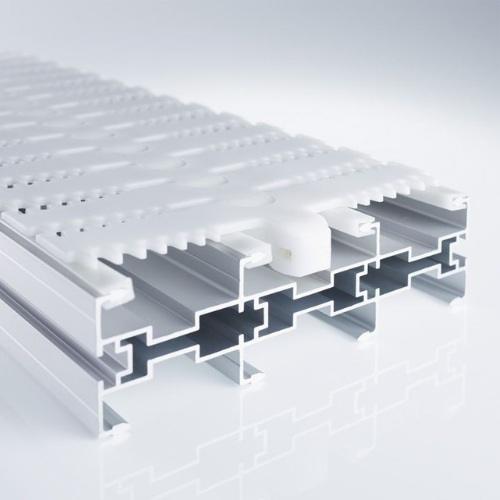

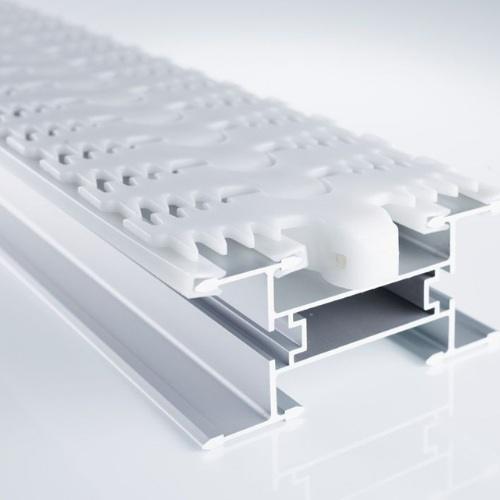

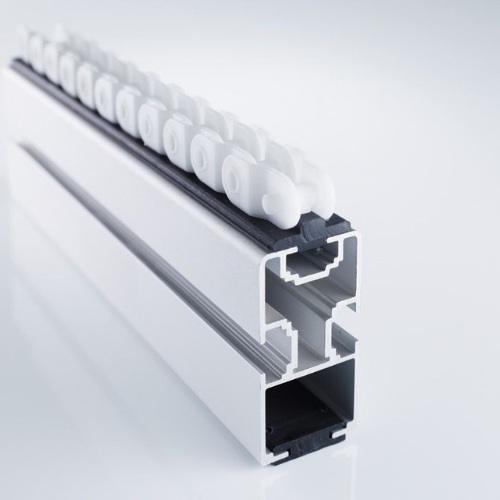

LVP Automation is the Irish distributor for Carryline Aluminium Slat Conveyors, offering a highly adaptable and space-efficient conveyor solution. Designed for versatile product movement across a range of industries, the Carryline Aluminium Conveyor integrates easily into both new and existing production or packaging areas. This modular system is built with durable aluminium components and can be set up quickly, allowing fast and cost-effective reconfiguration to meet changing operational needs.

Key Features & Benefits of the Aluminium Slat Conveyor

- Flexible Aluminium Slat Chain Design: Ideal for a variety of product movement needs, delivering adaptability for numerous applications.

- Modular, Space-Saving System: Maximises floor space efficiency, making it perfect for facilities with limited space.

- Easy Installation and Reconfiguration: The modular design allows for quick setup and adjustments, minimising downtime and reducing installation costs.

- Integration with PLC-Controlled Systems: Easily integrates into automated environments for smooth and precise operational control.