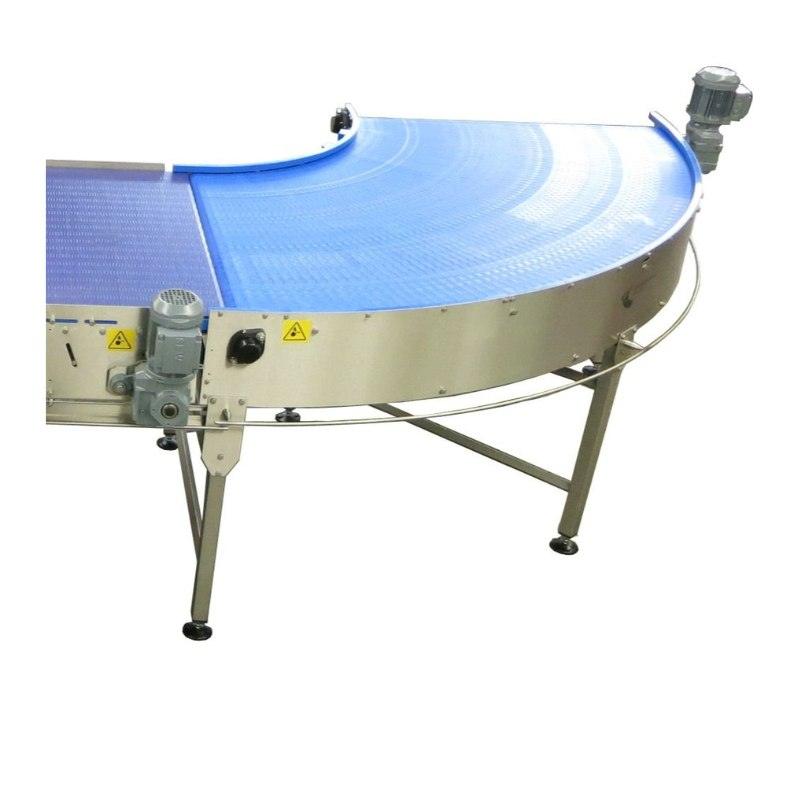

Modular Belt Conveyors

LVP Automation offers a robust selection of modular belt conveyors designed to meet diverse application needs across various industries. With a range of straight, radius, and inclined belt options, these conveyors are crafted from low-maintenance materials like Polypropylene, Polyethylene, Polyoxymethylene, and Polyamide for durability and minimal upkeep. Built with hygiene and durability in mind, our stainless-steel conveyor models are ideal for pharmaceutical and food processing environments, supporting easy cleaning to reduce contamination risk while ensuring lasting performance.

Key Features & Benefits of the Modular Belt Conveyor

- Wide Range of Modular Belts: Available in straight, radius, and inclined configurations to accommodate varied operational requirements.

- Durable, Low-Maintenance Materials: Constructed with high-quality polymers, including Polypropylene, Polyethylene, Polyoxymethylene, and Polyamide, for extended life and reduced maintenance.

- Hygienic Stainless-Steel Construction: Specifically designed for industries where hygiene is critical, such as pharmaceuticals and food processing.

- Easy-to-Clean Design: Minimises contamination risk, supporting safe and efficient cleaning procedures.

- Customisable for Any Application Size and Design: Flexible solutions tailored to meet unique industry specifications and space requirements.