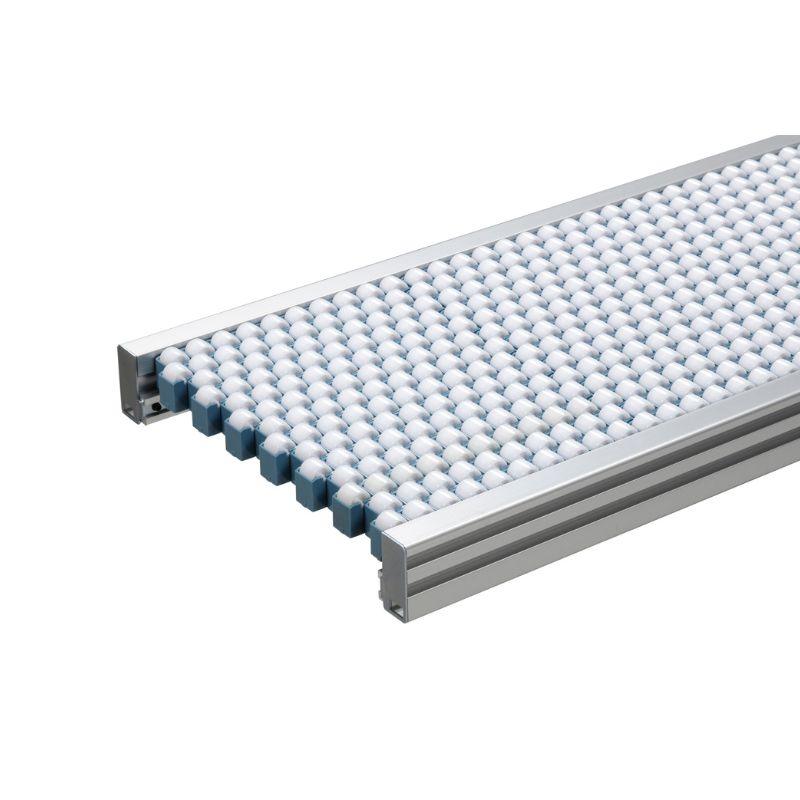

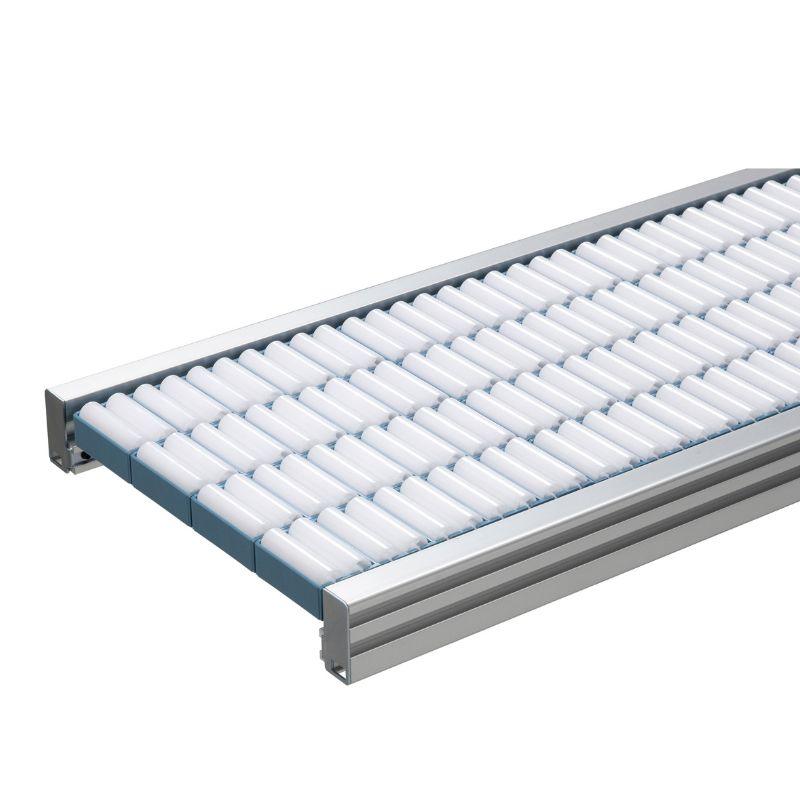

Light Duty Conveyors

Our most versatile non-powered conveyor, the General-Purpose Gravity Conveyor, provides a smooth and safe transfer for a range of cargo types, from lightweight items to heavy-duty loads. The gentle roller rotation allows for easy, controlled movement, making this conveyor an ideal solution for general material handling needs. With a focus on cost efficiency, ease of use, and labour-saving design, it’s well-suited for optimising workflows across various applications.

Key Features & Benefits of the Light Duty Conveyor

- Smooth Roller Rotation: Ensures safe, controlled transfer for both light and heavy items, reducing product damage and enhancing handling safety.

- High Cost Performance: Offers a budget-friendly solution without compromising on quality or functionality.

- Labour-Saving Design: Streamlines workflows and reduces manual handling requirements, boosting efficiency across work processes.

- Versatile Application: Suitable for a wide range of uses, from light manufacturing to heavy industrial settings.