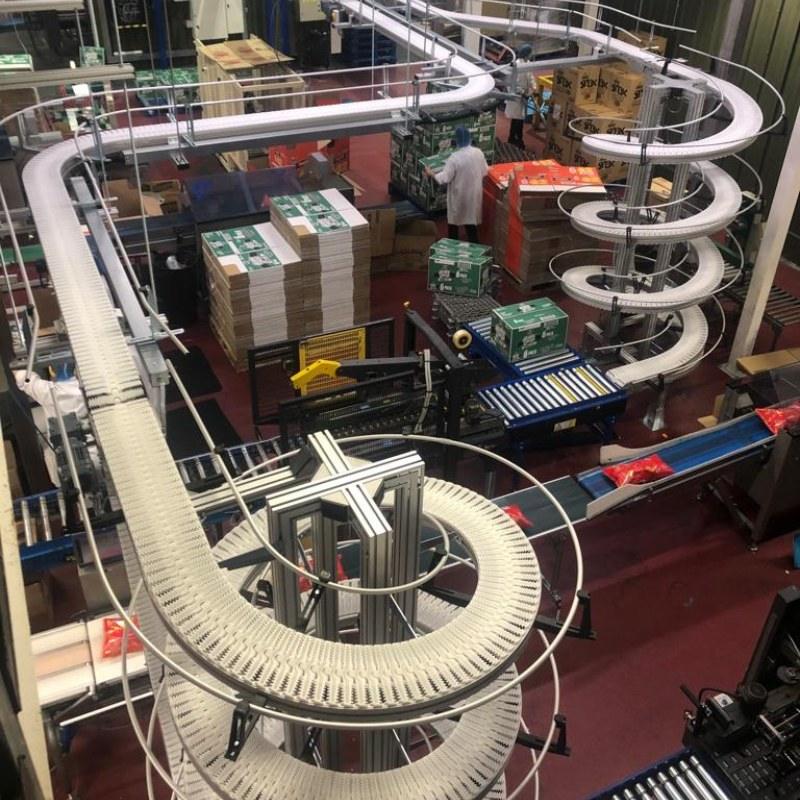

Slat Spiral Conveyor

The Carryline Spiral Slat Conveyor is an ideal solution for vertical conveying needs in spaces where a compact footprint is essential. This cost-effective conveyor system maximises vertical space while minimising floor usage, making it perfect for production environments with limited room. Built with minimal moving parts and common components, the Carryline Spiral is low-maintenance and designed for long-lasting performance. Available in aluminium or stainless steel, the modular design ensures easy upgrades and adaptability to future production needs.

Key Features & Benefits of the Slat Spiral Conveyor

- Compact Footprint: Utilises vertical space efficiently, freeing up valuable floor space for other operations.

- Low Maintenance: Minimal moving parts and standardised components reduce maintenance needs, lowering operational costs.

- Modular and Future-Proof: Easily customisable and adaptable to evolving production requirements, ensuring long-term utility.

- Available in Aluminium or Stainless Steel: Provides options suitable for various environments, including general and hygienic applications.

- Cost-Effective Design: Delivers reliable performance and flexibility at a competitive price point.